THE CLIENT

The Client is a U.S. exporter of Liquified Natural Gas (LNG) located in Texas by supercooling fracked gas and loading it onto seafaring tankers. With three train and 17 MTPA liquefaction facility is the largest all-electric drive motor plant of its kind in the world, making it the most environmentally sustainable site of its kind.

THE CLIENT'S REQUEST

In LNG processing, scrubbers are used to purify natural gas, removing impurities like water and carbon dioxide, hydrogen sulphides. The blowdown wastewater is highly concentrated with significant fouling potential. It contains pollutants requiring advanced treatment technologies with robust pretreatment steps to meet environmental discharge limits.

THE SOLUTION

Evaporation technology: 3 x AC R 6 FF

Construction material: UNS S32750

Overall dimensions on the ground: 3 x 9.9 sqm

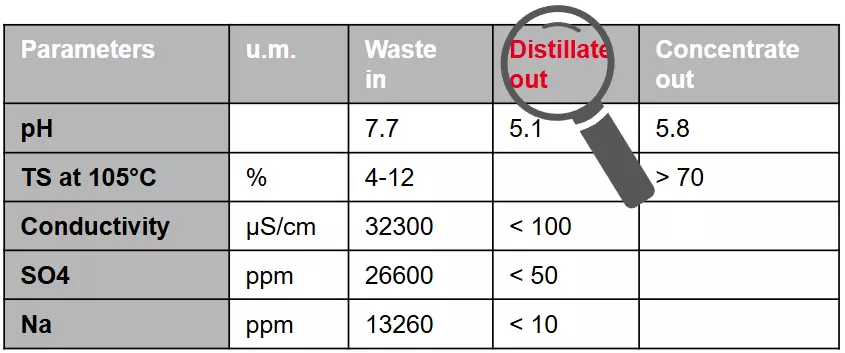

ANALYSIS OF MAIN PARAMETERS

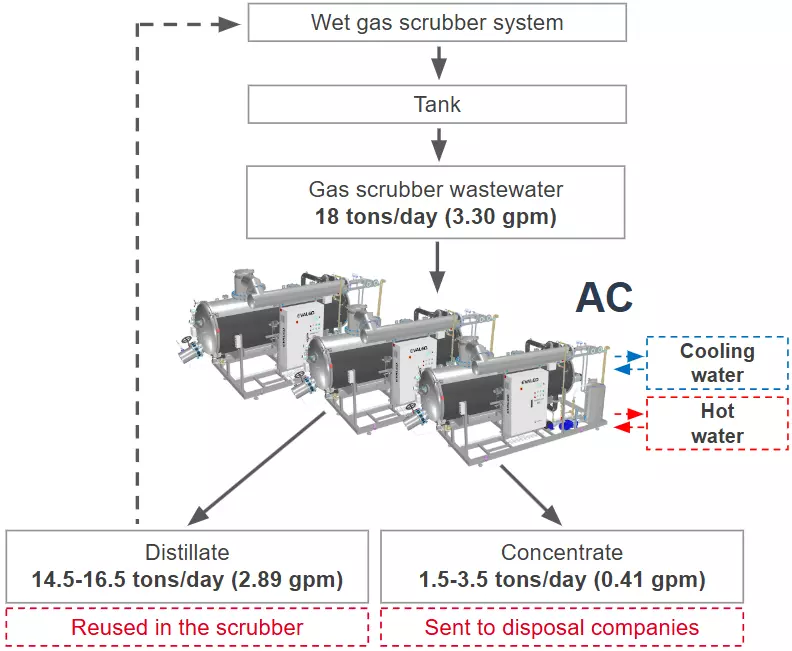

PROCESS DIAGRAM

- Water recovery: ∿80-90%

- Concentration factor: 6-18 times

- Distillate reused in the scrubber

- Disposal cost reduction

- Zero Liquid Discharge goal